Melting Point Apparatus Manufacturers

Sample preparation and machine operation tips for melting machine

Heating and cooling points play a vital role in various laboratory applications. The melting point is a temperature point where a solid material changes into another liquid. You might have seen ice that is a solid form of water and when you heat it or keep it in a warm environment, it melts. So the temperature point where it starts melting is called the melting point.

Melting Point Apparatus is an indicator of purity as the presence of impurities makes the changes in the melting points. So if the original gold has some particular melting point, it will change when it is impure. Therefore, the melting point helps in checking the substance’s purity.

Many industries purchase Melting Point Apparatus from their manufacturers to know the impurity in substances. Melting point determination is a well-recognized way that is easy and cost-effective for the business. You determine the impurity based on visual inspection of material.

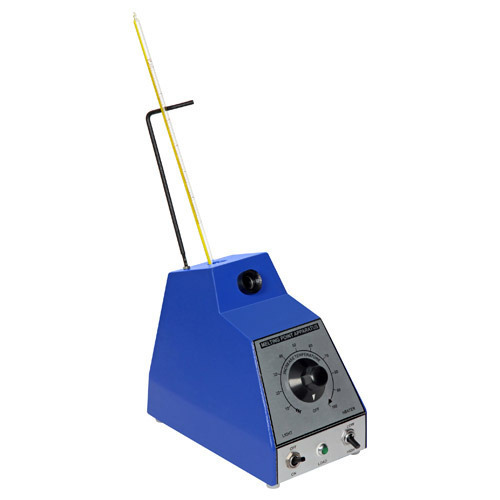

The material gets heated in the capillary tube. During heating, automated absorbance of liquid melts that ensures that there is no error due to bad personal observation. The machine is very useful but there you are required to take precautions while using it. Here is a blog that will guide you on various aspects of the Melting Point Apparatus manufacturers and suppliers and exporters in Delhi, India.

Ways to Determine Melting Point Apparatus

Melting Point Apparatus is a trusted basis for certifying the purity of any substance. But you can only be sure about the purity when the analysis is done properly otherwise you will get false results despite using the machine. Here are some steps to follow.

Preparation of samples is of utmost importance and it must be done properly. Properly prepare the material after firstly, arrange a capillary glass tube and a glass plate. Depose the sample at the open end of the capillary tube while ensuring that there is no leakage from the other end. The other end of the tube should be entirely closed.

Afterward, change the direction of the capillary tube into inverted mode and gently tap it. By doing that, you ensure that the sample reaches the bottom of the tube. Please note, do not put much weight on tapping as it may create trouble. Simply do the gentle tap. Keep doing the same step until the capillary tube is filled up to 2-3 mm with samples. Then use the tube with the machine to get the desired results.

Using tube with the Melting Point Apparatus

Put the capillary tube in the machine and turn it on. Start observing the temperature on the provided thermometer. The machine adjusts the heat by itself. Use the viewfinder located on the machine to keep a close watch on the substance. In the final stage, heat the material at the nearest point ideally less than 20 degrees below the known melting point. Slow down the heat so that there is a gradual increase in the temperature.

Conclusions

Hopefully, you have got good information about the functioning of the melting machine. Please ensure to purchase the machine only from authorized melting point apparatus suppliers, manufacturers and exporters in Delhi, India for correct results all the time.