Phone Number

+91-9891445495

-

-

Email Address

setestindia@gmail.com -

Global Certificate

ISO-9001-2015

Phone Number

+91-9891445495

Email Address

setestindia@gmail.com

Global Certificate

ISO-9001-2015

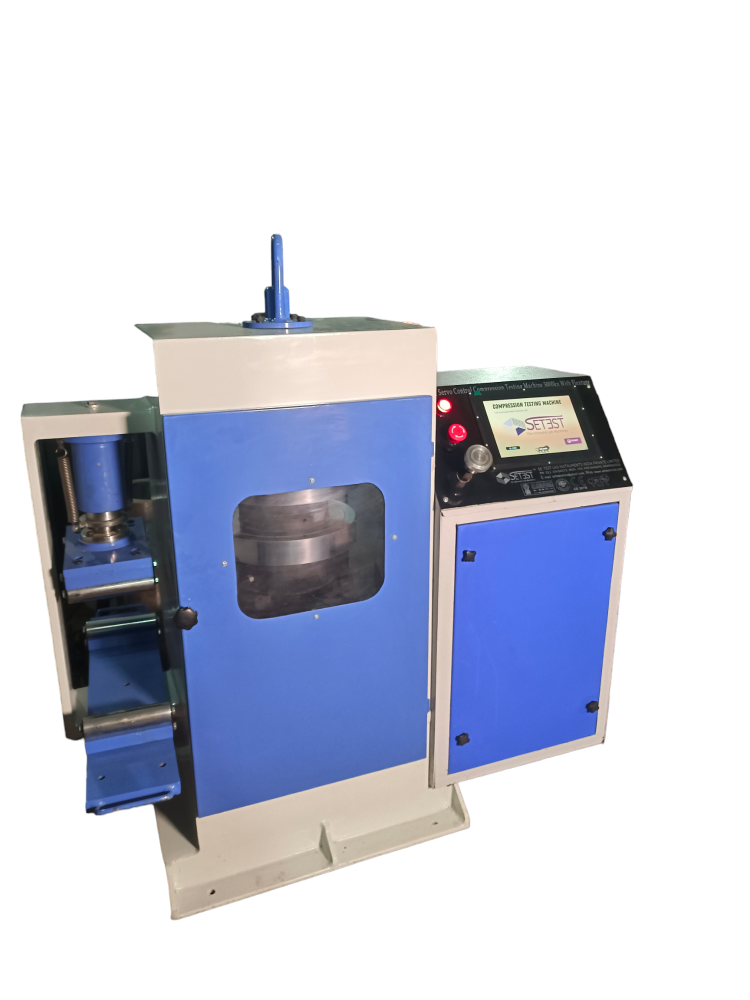

Fully Automatic range of compression testing machines supplied by SE-Test is one of the best in its range. The machine is perfect for meeting the requirement for a consistent and proper testing of the concrete samples. Our compression machines mainly comprise of the following important parts, i.e. Frame, Touch Screen, Control System and Power Pack with Servo motor. Each such important part of the machine has been fabricated with higher degree of care and mechanical adaptability to ensure smooth testing.

Load Frame:

The load frame may be a welded steel fabrication carrying the ball-seated higher platen. absolutely situated on the loading ram that is protected against trash by a canopy, the lower platen is marked for the centering of cube and cylinder specimens. the size of the frame permits the testing of concrete cylinders up to 150x320mm, 100mm, 150mm and 200mm cubes.

We are provided complete with 50mm and 100mm solid spacer for distance shorter. To check samples shorter than a hundred- and fifty-millimetre additional distance items ought to be ordered. All machines are furnished with front and rear removable safety doors. All frames have one acting up stroking ram with over travel protection to prevent the motor once the most platen travel be reached.

Touch Screen:

Power Pack

| Model | Unit | SET-1139-A | SET-1139-B |

|---|---|---|---|

| Capacity (L) | kN | 2000 | 3000 |

| Standard | IS14858:2000 | IS14858:2000 | |

| The roughness value fortexture of loading and auxiliaryplatens | µm | <3.2 | <3.2 |

| Lower platensdimensions | mm | Ø300 | Ø300 |

| Upper platensdimensions | mm | Ø300 | Ø300 |

| Maximum verticalclearance betweenplatens | mm | 340 | 340 |

| Pistondiameter | mm | 250 | 300 |

| Maximum pistonmovement | mm | 50 | 50 |

| Horizontalclearance | mm | 360 | 3380 |

| Power | W | 750 | 750 |

| Oilcapacity | Ltrs. | 20 | 20 |

| Maximum workingpressure | Bar | 600 | 600 |

| Dimensions (W x L xH) | mm | 810 x 500 x 970 | 840 x 540 x 1050 |

| Weight | Kg. | 795 | 1050 |

We adopt the principles of the creditable integrity to demonstrate our commitment to the client’s success. in today’s competitive market, particularly in the field of engineering equipments, SE-Test Lab is an honest and committed product supplier in the industry.

At SE-Test Lab, an effective team is committed to provide the best of products and services to meet all end-objectives of our clients. The team uses available resources, and every member works together as a single unit to deliver the best equipments for clients.

We always maintain an utmost level of quality in offering products or services, by means of providing minute attention to every stage of production, customization and delivery. By focusing on the quality management, we make sure to fulfill the quality requirements of clients.

Looking for a quality and affordable products